| Project 'Slomega' |

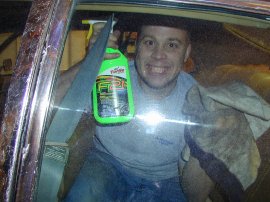

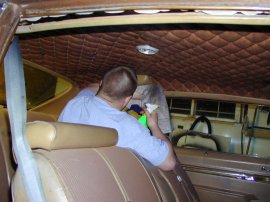

Now that everything is now or less complete, it's time to clean up the ol' car.

|

We then pause for something to eat ...

|

|

While eating, we came across a copy of the 'Vehicle Safety' manual and thought we'd give the car a once over before we take it in, in the morning for a safety check. At this point, my camera was stone dead and I have the batteries on charge.

Turns out there are a few things that will fail:

I don't know how Ian & I missed the hole in the floor and it's 11pm, what am I gonna do, the car is going in for a 'Safety Inspection' in less then 8 hours and was doomed to fail. We changed the right-rear tire with the spare & swapped seats from the Nova, over to the Omega so it would pass. We also temporarly patched up the hole in the floor. The day once again started off on another good note as I forgot the camera at home. We towed the Omega down to a garage for safety. The Omega passed and I was off to register the car, so it can now legally be parked on the front street, as I had no garage to park the car in and running out of places to stash it. Until more permanet repairs can be made, the Omega is still off the road. |

|

Noticed a small hole under the drivers floor and thought I could quickly patch it up. WOW!, NEVER PICK AT A SMALL HOLE!! So as I was using the Angle Grinder to clean up looking for good metal, the rear speaker wire got caught up in the grinder and ripped the grinder out of my hands. So now we have this flying grinder in the car, with the switch lock on. LOVELY!, as I drove out of the car to grab the power cord, I was caught in the line of fire.

Those big wire-wheels are SHARP!, this is after the aftermath of it going through 2 shirts I was wearing. Thanks to Glenn, who was pissing himself laughing from his kitchen and saw it all happen. I'm OK!

|

So my pinhole nearly turns into a needing a whole floor board. So looking around for some scrap metal, come across an old computer tower lid. That'll work!

|

So I made a pattern out of cardboard again, and then transfer it over to metal

|

I'll worry about the corner there in a minute. While I'm working on the floor, I took a moment to paint up some 15x7 steelies for the 245/60's I bought. Now it's time to weld and work on my welding tan.

|

Weld in the main piece of the patch and now come up with a smaller piece for that corner now.

|

So the driver's floor is all patched up, used a little monofoam to seal it up from underneath before I undercoat it lateron. Now time to rebuild the carb.

|

|

|

|

| Back to Pictures 2006 Menu |

|---|